Industrial shot blasting machine

Home / Shot Blasting machine

// Shot Blasting Machine

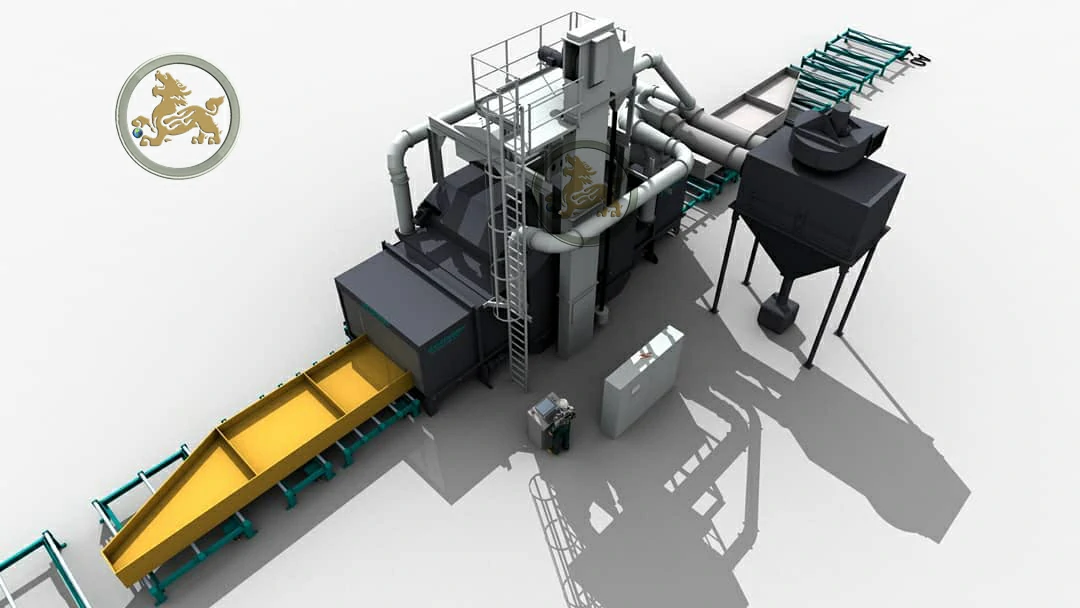

Industrial Shot Blasting Machine

Technology

Wheelabrator Blasting

Application

Multi-Industrial

Investment

Light / Medium / Heavy

Industrial shot blasting machine

I-track Hanger shot blasting machine

Design for the light load and low-efficiency work.

Function of industrial shot blasting machine

Sino-Abrator: Expert in High-Performance Shot Blasting Machines & Sand Blasting Equipment with Advanced Turbine-Wheel Tech, engineered with cutting-edge turbine-wheel technology for unmatched efficiency. Our equipment delivers precision in metal surface treatment and stone surface preparation, ensuring optimal performance for industries requiring rust removal, deburring, and surface cleaning.

Surface Cleaning & Rust Removal

Our shot blast machines excel in eliminating rust, scales, sand, and burrs from workpieces. Widely used in the foundry industry, they effectively remove sticky sand and oxide scale from steel and iron castings, ensuring surfaces are prepped for quality inspection or coating and painting.

Workpiece Strengthening & Surface Lifespan Enhancement

Leveraging shot-peening technology, our machines boost anti-fatigue properties and harden surfaces to prolong durability. This process aligns with modern metal strength theory, increasing dislocation stress to enhance structural integrity for automotive, aerospace, and industrial components.

Surface Preparation for Coating & Painting

Achieve the perfect roughened texture for adhesion with our abrasive blasting solutions. Ideal for delicate parts, our equipment ensures a flawless finish before protective coatings.

Main model of shot blasting machine

I-track Hanger shot blasting machine

Design for the light load and low-efficiency work.

Y-track Hanger shot blasting machine

Design for the light/medium load and work with alternative hooks.

Pass-through Hanger shot blasting machine

Design for the long & heavy load, and low-efficiency work.

Overhead carousel Hanger shot blasting machine

Design for the light load and high-efficiency work.

I-track Hanger shot blasting machine

Design for the light load and low-efficiency work.

Y-track Hanger shot blasting machine

Design for the light/medium load and work with alternative hooks.

Pass-through Hanger shot blasting machine

Design for the long & heavy load, and low-efficiency work.

Overhead carousel Hanger shot blasting machine

Design for the light load and high-efficiency work.

- Advantage

- Efficient

- Factor

Sino-Abrator’s shot blast machine seamlessly combines automatic processing with manual assistance, optimizing productivity while reducing labor costs.

Engineered for versatile surface treatment, our equipment enables reuse of shot abrasives like glass beads, steel shots, and steel grit, making it a cost-effective solution for industries demanding precision and sustainability.

Sino-Abrator’s shot blasting machine achieves exceptional surface preparation efficiency, delivering 200–400 m²/hour on cement, marble, and tile surfaces—ideal for large-scale industrial projects requiring rapid, uniform finishes.

Steel Plate Surface Blasting: Engineered for SA 2.5 to SA 3 steel grades, our equipment operates at 4m/min (SA 2.5) and 3m/min (SA 3), covering 75–100 m²/hour. Perfect for high-productivity steel plate treatment, ensuring compliance with stringent industrial standards.

Surface Condition

Evaluate contaminants (rust, sand, burrs) to determine blasting intensity for effective metal surface cleaning.Material, Size & Shape

Analyze part composition, dimensions, and complex geometries (including dead angles) to tailor blasting parameters.Shot-Abrasive Properties

Select abrasive hardness, size, and material (e.g., steel grit, glass beads) to match surface treatment requirements.Shot Wheel Turbine

Optimize turbine velocity, projectile capacity, and angle for consistent abrasive coverage and precision.Machine Working Condition

Monitor machine performance metrics (e.g., wear parts, airflow) to ensure operational efficiency.Post-Cleaning Processes

Align blasting speed with coating/painting preparation to maintain workflow consistency and finish quality.Environmental Compliance

Integrate eco-friendly shot blasting practices (dust collection, abrasive recycling) to reduce environmental impact.

Applications of airless shot blasting machine

- Foundry: Sand elimination, burr removal, scale stripping, and corrosion extraction for cast components (ductile/nodular iron, gray iron castings).

- Marble, Blocks, Bricks, Tiles, Kerbstones, Slabs & Cement: Texture stone surfaces, improve roughness, provide anti-skid properties, and offer decorative effects.

- Pipes: Clean surfaces for painting, coating, drilling, welding, etc,.

- Plates: Finish sheet surfaces for painting, coating, cutting, welding, and other processes.

- Forge: Burr elimination, microstructure homogenization, and temper scale eradication for forged surfaces.

- Aluminum die-casting: Surface refinement of die-cast aluminum parts.

- Gas cylinder: Texture smoothing and pre-coating purification for paint/primer readiness.

- Metal construction works: Post-fabrication cleansing (welds, cuts, drillings); stain and oxidation deposit removal.

- Shot-Peening: Enhances fatigue resistance and stress durability in mechanical parts.

- Customized-made: Tailored treatments for corrosion, polymer residues, granular contaminants, or unique surface requirements.

Detailed technical for hanger shot blasting machine

Airless Shot Turbines:

High-Performance Shot Turbines: Adjustable RPM range (2200–3800) to maximize abrasive velocity, paired with an optional electronic inverter speed control for precision adjustment and energy efficiency.

Spinning hanger:

Hanging system: 360° self-rotating hook spindle ensures full parts exposure during blasting, variable speed control and max. 10,000kg/hook lifting capacity and blast cleaning efficiency.

Shot blasting room:

Reinforced Cabinet Design: Built with a 12mm wear-resistant steel cabinet, welded reinforced construction, and 65 manganese-steel liners for unmatched abrasion resistance and long-term durability.

Separator:

Separator: integrates DISA and Pangborn technologies, efficiently sorting abrasives into three distinct classes with a remarkable 99.5% efficiency rate, ensuring high-performance separation in industrial applications.

Electrical control system:

PLC: operates across all voltage ranges, features comprehensive motor overload protection, and integrates an HMI for real-time monitoring of all components, ensuring operational safety and efficiency.

Elevator:

Elevator: lifts abrasive materials to the separator via a durable foundry-cast bucket, while an integrated tension device ensures belt stability, effectively preventing slippage during operation

Dust collect system:

Dust collector: employs a high-efficiency cartridge filtration system, achieving 99.9% effectiveness, with easily replaceable cartridges to streamline maintenance and ensure uninterrupted, hassle-free operational performance.

FAQs

What is "Shot blasting machine"?

What's industrial shot blasting machine price?

Airless shot blasting machine needs foundation base?

What is the shot abrasive use?

The shot blast machine efficient?

Shandong Sino Abrator manufacture co.,ltd

Tel./Whatsapp

+86 133 3333 234

INFO@SINOGRANALLADO.COM

Address

Haibin industry area, Huangdao District, Qingdao, 266400, CHINA

WE ARE WORLDWIDE

With our knowledge and experience, we are your reliable partner in manufacturing and assembly of wheelabrator blasting solutions worldwide.