Home / Sand Blasting equipment / Sand Blasting Room

// Sand Blasting Machine

Industrial sand blasting Room

Technology

Wheelabrator Blasting

Application

Universal

Investment

Medium / Heavy

Industrial sand blasting Room

Manual sand blasting room is engineered for manual or automated operation, utilizing compressed air to propel abrasive media through nozzles onto workpieces. These systems are custom-built to meet specific size, material, and application needs, tailored for processing large, heavy, or intricately shaped components like welded structures, foundry castings, forgings, railway wagons, die-cast parts, and shipping containers. They serve as a preparatory cleaning stage before coating or painting processes.

Constructed from modular steel panels or self-supporting insulated units with polyurethane resin, the chambers feature walls lined with durable, abrasion-resistant reinforced rubber. The floor integrates a metal grating system paired with screw or scraping conveyors, enabling automatic recovery and recycling of spent abrasive media beneath the blasting area. This design ensures efficient debris management and operational continuity.

- Feature & Benefit

- Industries Applications

- Technology

- Precision-Controlled Manual Operation

Expert manual handling ensures meticulous accuracy in every task. - Ideal for Flawless Surface Finishing

Delivers consistently smooth, polished results on a variety of materials. - Adaptable for Diverse Applications

Suitable for small to medium-sized components across industries—including castings, forgings, welds, and precision-machined parts. - Eco-Friendly Design

Zero-pollution process aligns with sustainability goals and environmental regulations.

- Foundry: Sand elimination, burr removal, scale stripping, and corrosion extraction for cast components (ductile/nodular iron, gray iron castings).

- Pipes: Clean surfaces for painting, coating, drilling, welding, etc,.

- Forge: Burr elimination, microstructure homogenization, and temper scale eradication for forged surfaces.

- Aluminum die-casting: Surface refinement of die-cast aluminum parts.

- Metal construction works: Post-fabrication cleansing (welds, cuts, drillings); stain and oxidation deposit removal.

- Shot-Peening: Enhances fatigue resistance and stress durability in mechanical parts.

- Wheel rims: Surface blasting finishing uniform.

- Customized-made: Tailored treatments for corrosion, polymer residues, granular contaminants, or unique surface requirements.

- Process: Manual sand-blasting ensures uniform finishing & efficient processing;

- Method: Fixed, rotary-table or cart/hanger transport system for wheelabrator;

- Surface finishing: Debris Removal, Corrosion Treatment, Paint Stripping, and Rust & Thermal Scale Elimination;

- Design: Standard & customised option is available as per requirement;

- Lead Time: 4 to 6 weeks;

- Investment: Medium / Heavy;

Detailed technical of Sand blasting system

Sand blasting machine:

SandBlasting: uses abrasive (glass beads or metal abrasive) and water of dustless blasting, propelled by compressed air (air compressor) as the power to projectile the surface.

SandBlasting:

Air Blasting: The dust blasting uses the mixed abrasive (glass beads, metal abrasive etc.,) and water without pollution; Manual operation for the small, medium and large parts (welded, castings, forgings, beams) to reach Sa 1.0 to Sa 3.0 level;

Sand blasting Shell:

Blasting Room: Built with modular or self-supporting steel panels insulated by polyurethane resin, featuring walls lined with reinforced, abrasion-resistant rubber; the floor is made from metal grating system.

Separator:

Separator: integrates DISA and Pangborn technologies, efficiently sorting abrasives into three distinct classes with a remarkable 99.5% efficiency rate, ensuring high-performance separation in industrial applications.

Electrical control system:

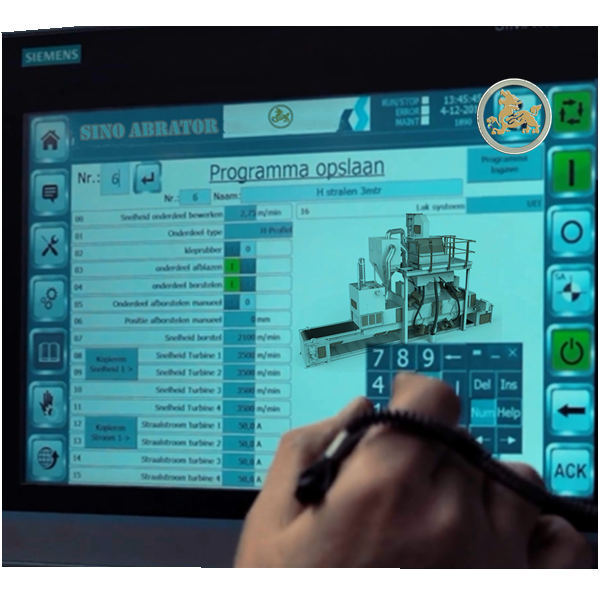

PLC: operates across all voltage ranges, features comprehensive motor overload protection, and integrates an HMI for real-time monitoring of all components, ensuring operational safety and efficiency.

Elevator:

Elevator: lifts abrasive materials to the separator via a durable foundry-cast bucket, while an integrated tension device ensures belt stability, effectively preventing slippage during operation

Dust collect system:

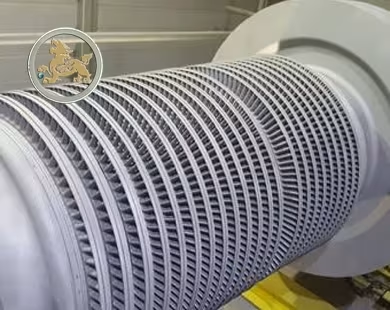

Dust collector: With a high-efficiency cartridge filtration system, achieving 99.9% effectiveness, easily replaceable cartridges to streamline maintenance & ensure uninterrupted, hassle-free operational performance.

Screw conveyor:

Abrasive conveying: The screw shaft is post-weld treated for coaxiality, while the 16Mn blade employs precision stretching and specialized processing for accurate pitch/dimensions, enhancing lifespan.

FAQs

What is a sandblasting room used for?

How does a sandblasting system work?

What types of abrasive media are used?

What factors affect the cost of a sand blasting room?

Surface Finishing solutions Projects

// Manual sandblasting for heat-treated, welded, castings, forgings, beams, steel structures etc., //

Shandong Sino Abrator manufacture co.,ltd

Tel./Whatsapp

+86 (189) 0639 2915

INFO@SINOGRANALLADO.COM

Address

Haibin industry area, Huangdao District, Qingdao, 266400, CHINA

WE ARE WORLDWIDE

With our knowledge and experience, we are your reliable partner in manufacturing and assembly of wheelabrator blasting solutions worldwide.